- The Upfit Insider

- Posts

- The Ultimate Guide to Choosing the Best Plow Truck for Your Snow Removal Business

The Ultimate Guide to Choosing the Best Plow Truck for Your Snow Removal Business

The Ultimate Guide to Choosing the Best Plow Truck for Snow Removal

The $200K Lesson

Highway department wanted air ride seats.

“Those are for comfort,” I said. Saved them $15K.

Three months later:

5 operators on workers comp

$200K in claims

Trust gone

Mechanic told me:

“You spec’d for a truck. Not a human.”

He was right.

The same mindset ruins snow plow fleets every winter.

Avoid six-figure spec mistakes. Founding Members get my ROI calculator + spec checklists for $5/mo (100 seats only). [Unlock Here]

What Is a Plow Truck?

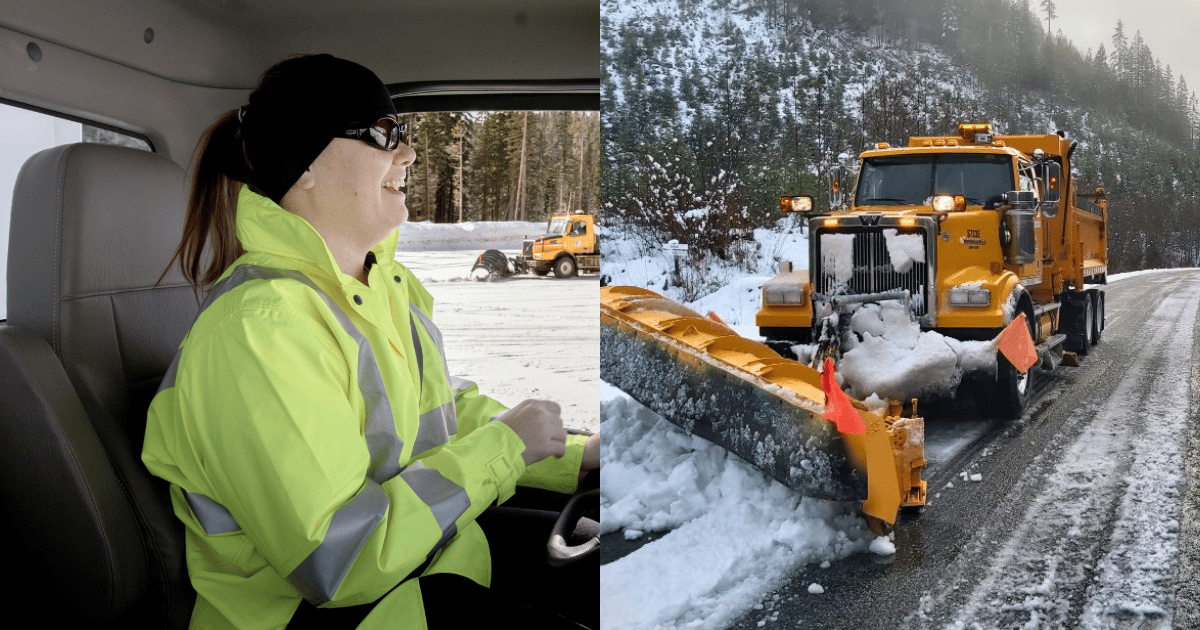

A plow truck is any work truck upfitted with a snow plow for a truck or a snow plow attachment for truck to clear roads, parking lots, or job sites.

Municipal fleets → DPWs, highway dept running every snow clearing truck through the night

Contractors → running a truck plow for commercial lots

Landscapers → adding a plow for truck to a pickup to create seasonal revenue

Stat: FHWA says snow removal eats up 20% of DOT winter budgets. Every bad spec = taxpayer money wasted.

Types of Snow Plows

Straight Blade

Cheapest option

Simple & reliable

Good entry-level snow removal equipment

V-Plow

Cuts through deep snow

Switches between V, straight, and scoop

More versatile for truck snow plow routes

Scoop

Efficient for big parking lots

Moves snow fast but less versatile

Key Factors When Choosing a Plow Truck

Truck GVWR Class

Class 2 (6,001–10,000 lbs): Light plowing, driveways, small lots

Class 3–4 (10,001–16,000 lbs): Core municipal snow clearing trucks

Class 6–7 (19,501–33,000 lbs): Highways, large city streets, airports

Core municipal snow clearing trucks. Specs here overlap with dump truck builds, so knowing how many tons a dump truck can haul helps buyers avoid axle and payload mistakes.

Attachment Compatibility

Not every chassis can handle a snow plow for truck setup — check specs before you buy

Check front axle rating and frame strength

Use OEM plow-prep packages to prevent frame or suspension failures

Power & Performance

Gas = fine for light duty

Diesel = better for municipal fleets & 24/7 use

Torque matters more than horsepower

Operator Ergonomics

A $500 seat upgrade can prevent a $40K+ workers comp claim

Skip ergonomics and you’ll pay in downtime, OT, and turnover

Use OEM plow-prep packages to prevent frame or suspension failures.

If you’re new to upfitting, here’s a full breakdown of what an upfit on a work truck really means so you understand how plows, spreaders, and other bodies tie into the chassis.

Must-Have Features

Hydraulics: Reliable lift/angle, easy to service

Lighting: LED + heated housings for night storms

Safety: Heated mirrors, backup cameras, ergonomic seating

Installation & Maintenance

Install Tips

Always use OEM plow-prep kits

Reinforce hydraulics & electrical connections

Confirm axle capacity before mounting

Maintenance

Inspect before every storm

Wash salt off after every run

Rotate cutting edges regularly

Always use OEM plow-prep kits. Reinforce hydraulics & electrical connections. If you want to dive deeper into snow season prep, check out Snowplow Prep 2025: Why Setups Fail (And How to Prevent Them).

ROI of Spec Decisions

Skip air ride seats: Save $7,500 → lose $150K+ in comp & downtime

Cheap steel blades: Save $1,500 → replace twice as often, lose money

LED + heated lights: +$2,000 → prevent accidents, ROI priceless

Plow-prep package: +$3,000 → avoid $20K frame failure, ROI win

Winter downtime costs fleets real money. Founding Members get the Snowplow Mastery Guide free ($5/mo, 100 seats). [Join Now]

Hypothetical Fleet Scenario

Picture this:

A DPW specs 10 truck plows, skips seat upgrades to save $15K.

By mid-season, 3 operators file comp claims for back injuries.

Remaining crews work OT, with each truck plowing snow twice as long to cover routes.

Total hit = $180K in claims + OT + lost trust.

That’s not an accident. That’s the cost of ignoring ergonomics.

FAQs

What is the best truck class for plowing snow?

Class 3–4 trucks (10,001–16,000 lbs) are the sweet spot for municipalities. Class 6–7 trucks are best for highways and nonstop plowing.

Are V-plows better than straight blades?

Yes for versatility. Straight blades are cheaper but less efficient.

How much does a snow plow installation cost?

$3,000–$7,000 depending on truck class, hydraulics, and lights.

What can I do with a snow plow truck?

Use it for municipal clearing, contract lots, or seasonal private work. Many fleets offset downtime by renting snow plow trucks to contractors.

Wrap-Up: Spec for Humans, Not Trucks

Cheap specs = expensive mistakes.

Smart specs = safe operators, more uptime, fewer claims.

Snow season exposes mistakes fast. Fleets that spec for humans, not just trucks, come out ahead every time.

Snow season is here. Don’t spec blind. Founding Members get the Snowplow Mastery Guide + ROI tools for $5/mo (100 seats). [Get Access Now].

Your move: What’s the worst snowplow mistake you’ve seen a fleet make?

—

Leyhan

Founder, The Upfit Insider

Reply