- The Upfit Insider

- Posts

- Fleet Downtime: Why Work Trucks Fail & How to Prevent It

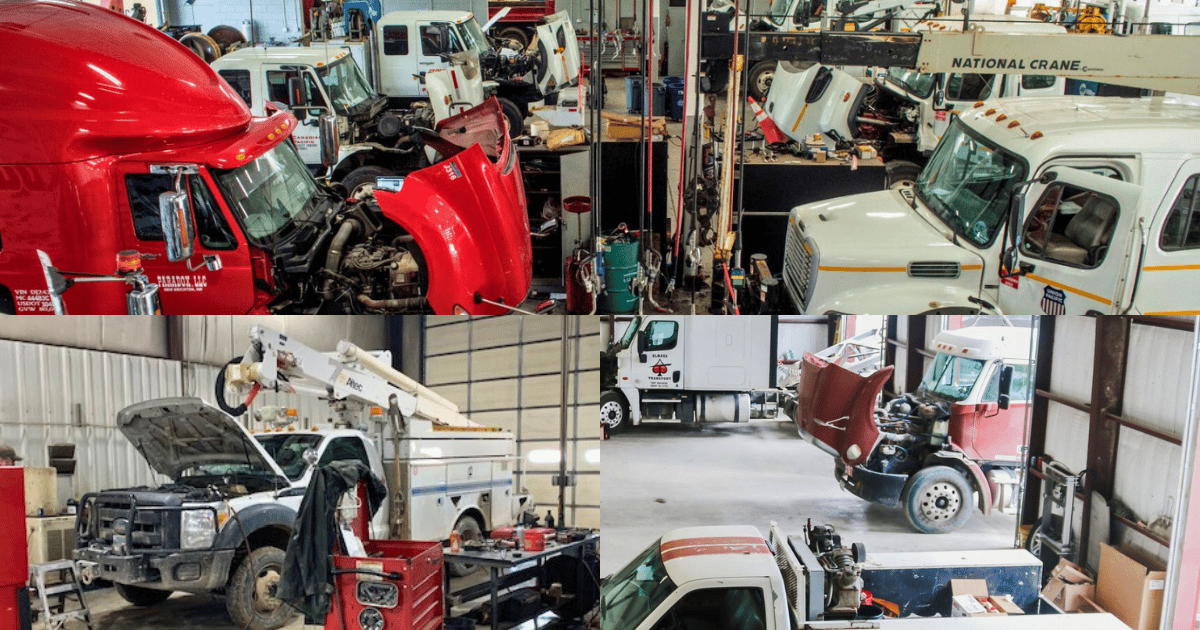

Fleet Downtime: Why Work Trucks Fail & How to Prevent It

Every day of downtime drains $400–$750 per truck. Here’s how spec failures drive repair costs — and how to protect fleet uptime.

Fleet Downtime: Causes & Costs Explained

That brand-new truck?

Back in the shop again.

Not because the engine or chassis failed — but because the upfit was rushed, built wrong, or spec’d with zero long-term thinking.

Here’s the truth: truck downtime costs are never just repair bills. Every idle day eats into revenue, racks up rental fees, and erodes customer confidence. Scale that across your entire fleet size, and suddenly you’ve got six figures leaking from the balance sheet.

Downtime kills profit. Fleet uptime is the real competitive edge.

🚨 Avoid a $20K spec mistake. Run your numbers in real time with my Work Truck ROI Calculator: TCO Explained. Founding Members: $5/mo (100 seats). [Unlock the Calculator]

Why Work Trucks Keep Breaking Down

Answer: Downtime isn’t caused by drivers. It’s caused by bad specs and sloppy installs.

I’ve lost count of how many fleet managers have told me:

“We spec’d this truck right — but it’s always back in the shop.”

Then we crawl under the frame, and the picture gets ugly:

PTO installed without heat shields → wires melted before 5,000 miles

Toolboxes flexing against the body → cracked frame rails by winter

Brackets welded after paint → stress fractures guaranteed

Undersized compressors → jobsite air tools stall out, killing uptime

Strobes wired direct to brake circuits → dead batteries first cold Monday

None of this shows up on delivery day. It shows up in the fleet maintenance program months later — when you’re paying techs overtime for problems that should’ve been prevented.

This isn’t “normal wear.” It’s engineered downtime. It’s the real cost of ownership (RCO).

The Real Cost of Fleet Downtime

Answer: Vehicle downtime bleeds cash faster than any invoice.

Industry data shows unplanned downtime costs fleets $300–$1,000 per day, per truck. Fleet Maintenance sets the average at $400–$750.

That doesn’t sound huge until you add it up:

Minor repair delay → $400/day lost

Component failure → $750/day lost

Rental + missed jobs → $1,000/day lost

Now stretch that across a 10-truck fleet:

“Minor” delays = $8,000/year

Recurring failures = $15,000/year

Rental gaps = $200,000+ annual loss

This isn’t just truck repair costs or truck maintenance costs. It’s fleet repair costs snowballing into missed contracts, wasted payroll, and broken trust.

OEMs like Freightliner Trucks push their “Real Cost of Ownership” pitch for a reason. They know total cost of ownership (TCO) isn’t about sticker price. It’s about uptime, repair velocity, and parts access. If you ignore downtime, your cost per mile doubles before you even notice.

How Bad Upfits Drive Up Repair Costs

Answer: Bad installs fast-forward your replacement cycle.

Your fleet vehicle lifecycle replacement cycle shouldn’t crater at year three. But it will if the build itself is flawed. That’s when maintenance expenses balloon past budget, and your “six-year plan” becomes a three-year headache.

The biggest killers I see:

No torque logs → mounts loosen, pumps shift, brackets snap

Wiring shortcuts → corroded harnesses, strobes dead by spring

No axle load sheet → overloaded rears wipe out brakes and suspension

Dealer-to-builder gaps → wrong chassis shows up, shop “makes it work”

This doesn’t just hit your shop. It wrecks your fleet maintenance program. Instead of preventive PMs, you’re doing forensic repairs. Instead of extending life, you’re accelerating replacement cycles.

If you’re new to this world and wondering exactly what “upfit” really means, I broke it down in What is an Upfit on a Work Truck? It’s worth reading before your next spec meeting.

Checklist: Prevent the Most Common Fleet Failures

Answer: Accountability is uptime’s best friend.

The no-fluff list high-performing fleets use to eliminate downtime surprises:

✅ Torque-log every mount, pump, and bracket

✅ Match PTOs to real jobsite GPM demand — stop guessing

✅ Sync strobes with OEM harnesses — prevent ghost draws and dead batteries

✅ Spec for terrain — rural fleets need clearance, urban fleets need tighter, tougher builds

✅ Require builder sign-offs — written, photo-verified, itemized

✅ Archive CAD drawings, wiring diagrams, torque specs — no more missing records

✅ Verify axle load distribution before delivery

Pro tip: Add a 30-day post-delivery inspection. Most failures show up in the first month — catching them early extends lifecycle, reduces vehicle downtime, and keeps your TCO on track.

Fleet Upfit Trends That Actually Protect Uptime

Answer: Smarter spec decisions save money before the truck hits the road.

Kenworth T880E Factory PTO Options → prewired, no hack installs

Knapheide PGTC Gooseneck Body → tighter packaging = longer lifespan

VMAC UNDERHOOD® Air Systems → lighter, fewer moving parts, cleaner installs

Buyers Products Toolbox Mounts → prevent flex stress and frame cracks

Magnum Bolt-On Headache Rack → pre-drilled strobes, fast swaps, fewer rewires

Each upgrade is an investment in fleet uptime, fuel economy, and predictable maintenance expenses.

And if you’re spec’ing a new utility body, read my breakdown on Choosing the Right Utility Service Truck Body. Picking wrong there can bake downtime into your next 10 years.

⚡ Want to know if a spec change really pays off? Run my ROI Calculator. Five minutes, real-time numbers, zero guessing.

FAQs: Fleet Downtime, Costs & Prevention

Q: How much does fleet downtime cost per day?

A: On average, $400–$750 per truck, per day. With rentals and missed work, it can hit $1,000/day.

Q: What causes most work truck downtime?

A: Not the chassis. It’s almost always the upfit — torque specs skipped, bad wiring, undersized PTOs, overloaded axles.

Q: How do I prevent downtime in new trucks?

A: Demand torque logs, axle load sheets, and builder sign-offs. Add a 30-day inspection. Pair it with a strong fleet maintenance program.

Q: How does downtime affect total cost of ownership (TCO)?

A: Downtime inflates maintenance expenses, cost per mile, and replacement cycles. That’s why OEMs like Freightliner Trucks emphasize the real cost of ownership (RCO).

Final Word: Don’t Let Downtime Wreck Your Bottom Line

Here’s the simple math:

Unplanned downtime = wasted payroll, lost contracts, broken trust

Fleet uptime = jobs delivered, operators retained, profit in the bank

The average fleet loses $10K+ per truck, per year in preventable downtime. That’s cash you’ll never get back.

So stop treating downtime as “just part of the business.” Spec smarter, demand accountability, and align your build with the true cost of ownership.

Because downtime isn’t fate. It’s a decision — yours.

💡 Want to stop gambling on specs? Join The Upfit Insider. Founding Members get my ROI Calculator, spec checklists, and weekly field-tested strategies — all for $5/mo (100 seats only). [Join Now]

👉 What’s the worst downtime disaster your fleet’s ever faced — and what did it really cost?

—

Leyhan

Founder, The Upfit Insider

Reply