- The Upfit Insider

- Posts

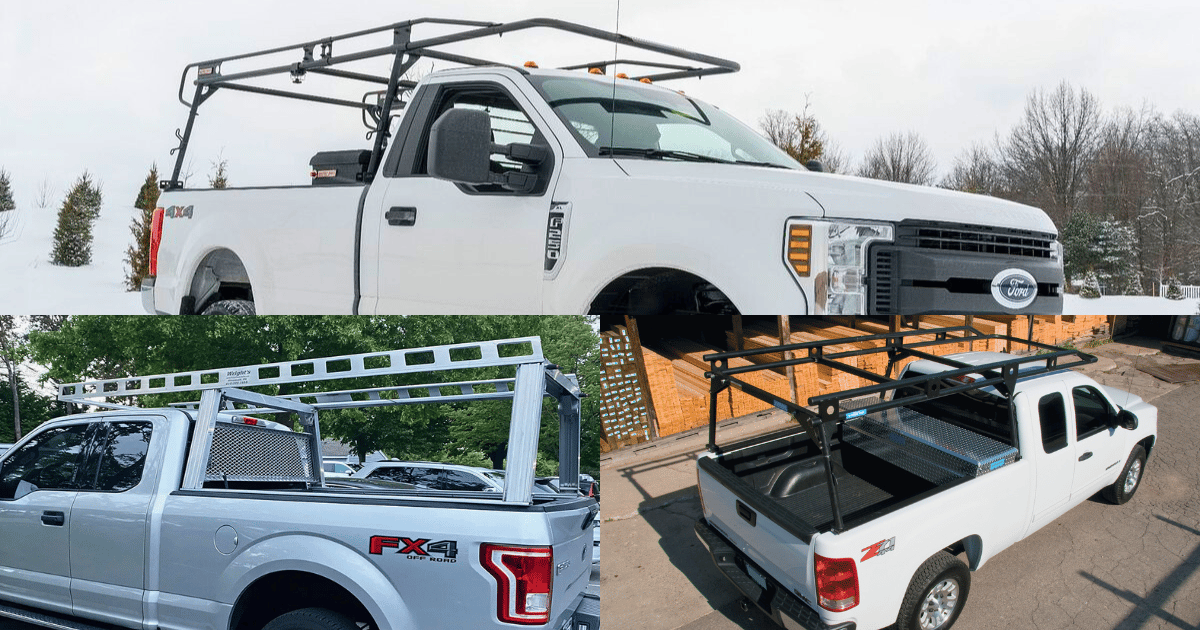

- Work Truck Ladder Rack Guide 2025

Work Truck Ladder Rack Guide 2025

Stop losing ladders and downtime — our 2025 ladder rack guide shows how to spec the right rack system for safety, cargo capacity, and ROI.

Ladder Rack Guide for Work Trucks (2025)

Why Ladder Racks Matter for Fleets

If your crews haul ladders, conduit, or pipe, a ladder rack isn’t optional. As essential as the truck itself. The right ladder rack for truck applications keeps gear secure, operators safe, and inspectors off your back.

The best rack systems give fleets real ROI because well-built racks offer more than storage — they deliver uptime and compliance.

Spec the wrong setup? You waste time, damage equipment, and risk liability.

Spec it right? You keep crews efficient, compliant, and productive.

Fleet managers who think of racks as an afterthought end up paying later in downtime and repairs. A properly spec’d truck ladder rack turns a work truck into a tool that makes money every day.

One wrong spec can wreck your budget. I broke down the worst offenders here: 7 Spec Mistakes That Cost Fleets Thousands.

Best Ladder Rack Brands for Work Trucks (2025)

When fleets ask, “What is the best ladder rack?” these are the brands that stand out:

System One — premium aluminum with integrated tie-downs, built for payload savings.

Weather Guard — heavy-duty high quality steel and aluminum, trusted by contractors nationwide. Often backed by limited lifetime warranty.

Buyers Products — dependable value for fleets that need durability at scale.

Adrian — versatile steel/aluminum systems tailored for vans and light-duty service trucks.

Prime Design — ergonomic aluminum drop-down ladder racks for truck vans where operator safety matters most.

Each has its place. The best rack depends on whether you’re outfitting a pickup, van, service body, or dump.

Download the Ladder Rack Comparison Chart (2025)

|

Straps and Tie Downs: Lock It Down Right

A rack carries the ladders, but straps do the real work. A truck rack without the right tie downs is just a liability waiting to happen.

Strap Types:

Cam buckle — quick jobs, light ladders, but prone to loosening.

Ratchet — heavy-duty, daily use, locks tight.

Velcro — only for light gear, limited strength.

Retractable — best for fleet trucks with constant turnover, trades convenience for load rating.

Hardware Upgrades:

Rubber-coated hooks

UV-rated straps

Lockable tie downs

Rear rollers for easy loading

Many modern rack styles now have adjustable load stop bars and strong cross bars. These features keep ladders and conduit from moving during transport.

Large retail store straps fail quickly. Pro fleets spec System One or Buyers winches that hold up on truck bed racks through years of use.

Skip the cheap gear. To understand why fleets end up bleeding money on repairs, check out: Why Your Work Truck Is Always in the Shop (And How to Stop It).

Work Winches: Secure Gear the Right Way

Skipping a winch on a rack for trucks is a rookie mistake. Always make sure your winch rating matches the rack’s weight capacity, or you risk damaging both the system and the load.

Types of Work Winches:

Square tube — bolts to steel racks, ~500 lbs WLL.

Round tube — clamps to aluminum racks, ~500 lbs WLL.

Bolt-on — mounts to stake rails or frames, 5,000+ lbs for heavy hauling.

Retractable — fleet-friendly, 500–5,000 lbs capacity, fastest for high turnover.

Without winches, even the strongest truck racks bleed money in damaged ladders and downtime.

Steel vs. Aluminum: Which to Choose

Steel Ladder Racks:

More rigid and affordable.

Easy to weld, fix, and reinforce.

Ideal for punishment-heavy fleets.

Aluminum Ladder Racks:

Rust-resistant and lighter weight.

Increase payload capacity.

Better ROI for fleets focused on efficiency.

Rule of thumb: Use steel when you can guarantee abuse, and choose aluminum when you need weight savings and longevity.

Aluminum truck operators enjoy lighter weight and save on fuel. Aluminum truck racks help fleets carry more and resist rust. Some fleets even spec stainless steel alternatives for extreme conditions.

Both options are available for pick up trucks, service bodies, and vans. Choose the truck racks style that matches your load type — ladders, conduit, or long cargo.

Choosing steel vs aluminum is just one part of the equation. Payload matters too — here’s the full breakdown: Dump Truck Capacity Chart (2025 Edition).

Fitment: Matching the Right Rack to the Right Truck

Work Trucks

Style: Over-cab, side-mounted truck ladder racks

Capacity: 800–1,250 lbs

Notes: Most ladder racks for pickup trucks attach over the cab or along the rails. This depends on the style and cargo capacity of the truck rack.

Vans

Style: Roof-mounted, drop-down ladder rack for van setups

Capacity: 300–700 lbs

Notes: Many van racks use a track system that allows adjustable cross bars and accessories like rollers or clamps.

Service Bodies

Style: Over-cab, utility side truck bed racks

Capacity: 500–1,000 lbs

Notes: Often spec’d with removable rear bar for versatility

Dump Bodies

Style: Cab protector and rear post racks for trucks

Capacity: 500–1,000 lbs

Notes: Custom setups avoid tilt and dump clearance issues

FAQs: Ladder Rack Specs & Safety

What is a ladder rack?

A mounted system that lets fleets carry ladders, pipe, or long cargo safely while freeing up bed or cargo space.

Are ladder racks universal?

Some adjust, but most designers create them for specific chassis — pickup, van, service body, or dump.

How much weight can a ladder rack hold?

Most truck ladder racks hold between 300–1,250 lbs depending on material (steel or aluminum) and vehicle type.

What are the benefits of using a ladder rack?

They secure ladders, keep crews safe, free up cargo space, and prevent DOT violations.

What is the best ladder rack?

System One and Weather Guard lead in durability. Buyers Products balances price and strength. Adrian serves van operators, while Prime Design dominates ergonomic drop-down truck roof rack setups.

Do ladder racks work with headache racks and tonneau covers?

Yes. Some fleets combine ladder racks with headache racks to protect rear cab glass. Certain manufacturers also design racks to work with tonneau covers by using rail-mount track systems.

Can ladder racks carry more than ladders?

Yes. Bed racks for trucks can handle ladders, kayaks, pipe, and conduit. Some companies even adapt similar designs for bike racks and other gear.

Final Word

A ladder rack for trucks is not just an accessory. An important choice affects uptime, safety, and return on investment.

Choose steel when abuse is certain. Choose aluminum when efficiency pays back over years. And always spec the right rack for your truck based on the body style and workload.

Cut corners here, and your fleet pays for it later. Get it right, and your truck bed rack becomes one of the most valuable tools in your operation.

🚨 Only 100 Founding Member spots available — 61 left.

For just $5/month, you lock in lifetime access to:

4 expert article collabs with me each year

Work Truck ROI Calculator

Snowplow Mastery Guide

Operator Ergonomics Playbook

Future exclusive perks

Once the 100 seats are gone, price jumps to $15/month.

👉 Secure your spot now and start building smarter fleets.

—

Leyhan

Founder, The Upfit Insider

Reply